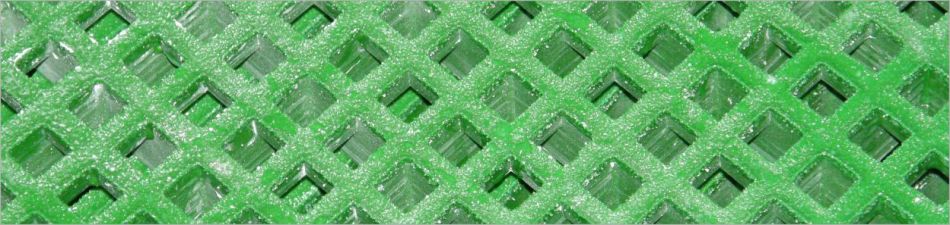

Our moulded fibreglass grating is made up of a one piece, interwoven, square mesh constructuon, composed of approximately 65% resin and 35% continuous filliment fibreglass roving.

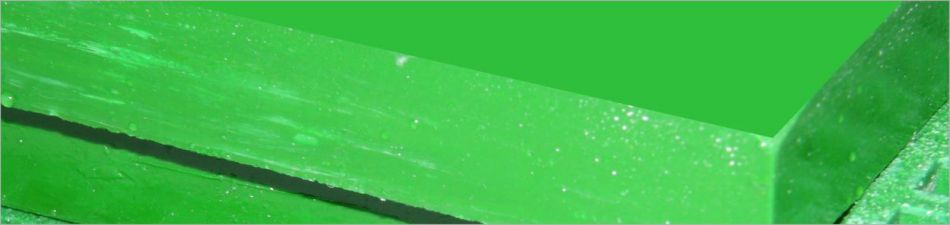

The fibreglass roving, together the liquid resin, is methodically placed in a mould, in layers until the required thickness is achieved. It is then set aside for curing.

We stock both Polyester and Vinyl ester resin grating. The Isophthalic polyester resin gives it resistance to corrosion in the marine and most chemical industries whilst the Vinyl Ester resin is used mainly where there is a concentration of acids.

At our premises in Cape Town, we have a large table saw and extractactor fan which enables us to cut our grating safely, to our customers requirements.

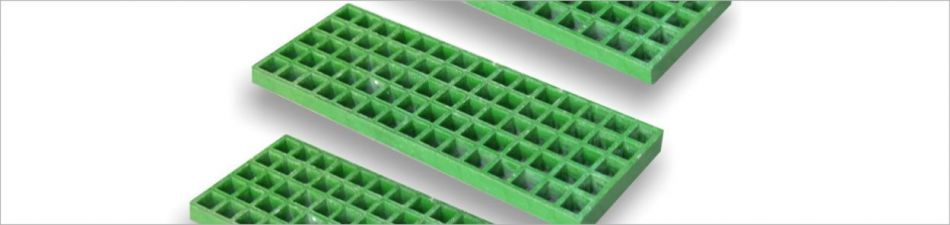

Our moulded fibreglass grating is available in various panel sizes and profiles. See our Panel sizes and profile page.

This product is used to prevent accidents occuring from small tools and other objects falling through to the walkways below.

They are also ideal for areas where light and or airflow is essential, as well as for machine guards.

Due to the closeness of the bearing bars, it makes it easier for light weight trollies and wheelchairs to pass over.

This product is used to prevent liquids and small particles falling through.

The open and closed grating steps are cut to size according to the clients requirements.

The open grating with its concave meniscus, quartz stone grit surface and the spacing between the bars, provide an extremely good traction.

These covers are manufactured in isophthalic polyester resin and therefore are corrosion and fire resistant.

The coarse quartz stone gives it the non-slip saftey qualities, whilst the yellow and black colours enhances its saftey aspects.

They can be used on fire escape steps, as well as on the steep staircases of the marine vessels.